Corrosion resistance charts are a great resource to use to find suitable alloys for a given chemical service. However, pay attention to the footnotes and read supporting literature as well, because those corrosion charts are really only reflecting general corrosion with the posted numerical values. One of the other types of corrosion that needs to be considered is crevice corrosion.

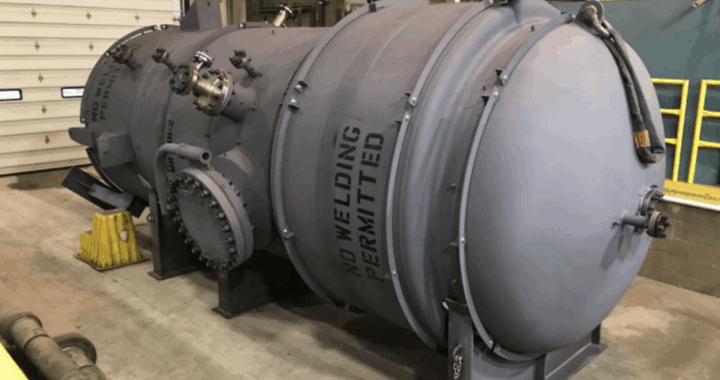

Figure 1 An immersion coil in Tricor’s shop for repair. There are many potential places for crevice corrosion in this design, like where the tubes contact the support beams and the u-bolts around the tubes.

Crevice corrosion is a localized form of corrosion that occurs when a corrosive fluid becomes trapped in the crevices, cracks, or joints of metal surfaces or under deposits. Crevice corrosion initiates in these confined spaces, where the access of oxygen and other oxidants is limited. The presence of stagnant conditions, often caused by capillary forces, allows for the accumulation of corrosive agents within the crevice. Over time, the passive layer, which normally protects the metal from corrosion, can be compromised due to the restricted supply of oxygen and the accumulation of aggressive substances.

There are some important fabrication techniques that can help prevent or reduce crevice corrosion:

- Avoid Overlapping Joints: Overlapping joints can create crevices where corrosion

may initiate. Whenever possible, use butt joints to minimize gaps. - Use Continuous Welds: Specify continuous welds instead of spot or stitch welding to reduce the chances of crevice formation.

- Design to Eliminate Crevices: Design components to avoid features that could trap

fluids or debris, such as sharp corners or tightly fitting parts. - Ensure Good Weld Quality: Make sure that welded joints achieve full root

penetration and avoid undercuts or cracks. - Minimize Complex Weldments: Simplified designs reduce the risk of creating small, inaccessible spaces where crevices can form, improving weld quality overall.

- Avoid Stagnant Zones: Ensure that the pressure vessel design avoids areas where fluids could become stagnant, as this is a primary factor in crevice corrosion. This can include ensuring proper drainage and avoiding dead zones in the design.

If crevices are unavoidable, another approach is to upgrade to a more corrosion resistant alloy in those areas. For example, titanium Grade 7 is generally more resistant to crevice corrosion compared to Grade 2. So, on a titanium Grade 2 vessel design, Grade 7 material can be used in areas where at risk for

crevice corrosion:

- Grade 7 material for lap rings/stub ends on all body flange and nozzle connections.

- Grade 7 filler metal in all process-wetted Grade 2 vessel weld joints.

- Grade 7 material for all vessel internals that have crevices where process fluid may sit or

become stagnant.

By integrating these fabrication practices, the risk of crevice corrosion in pressure vessels can be significantly mitigated, ensuring long-term reliability and safety of the equipment.