Positive Material Identification (PMI) - Astrolite Alloys

PMI is an examination of welding wire and security-relevant components in regard to the used material. It’s on spot, non-destructive and verifies the compliance of the chemical composition of the materials used. Instead of relying on certificates of composition. PMI verification confirms that the alloy is as specified, check if the grade is as expected. This is of central importance to weldability and durability to ensure safe practices.

PMI is used by Astrolite as one of the FOD prevention measures we have in place. Utilizing two methods of PMI as required by our customer’s specifications.

- Thermal Electric Alloy Sorter (TEAS) – TEAS is the most efficient and inexpensive method available for sorting various alloys, such as stainless steels, titanium, aluminum, and more. Each test takes only one second. Get rapid, testing results. TEAS is excellent in determining dissimilar materials i.e. Stainless Steel vs. Titanium. Astrolite performs 2 different 100% inspection options for our customers.

- • Use of an test procedure with multiple rods tested at one time we greatly lower cost and testing time

- • Individual rod inspection is conducted per customer section requirements

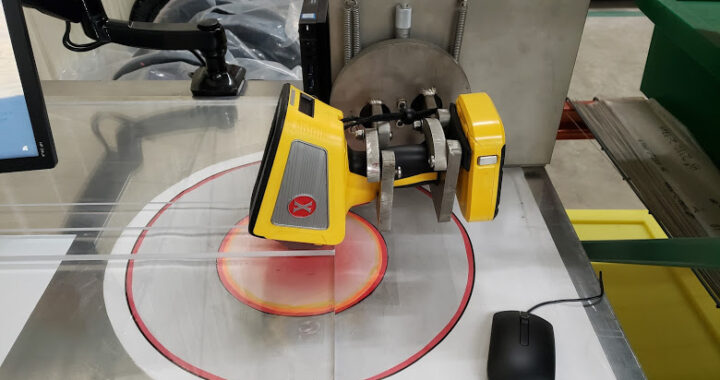

- X-ray Fluorescence (XRF) – XRF works by exciting the electrons in atoms, causing a change in energy, which is then detected by the instrument’s detector. XRF provides specific chemistry verification of the alloy being tested. Other PMI methods may have difficulty distinguishing between alloys of the same base material i.e. Titanium Gr 1. vs. Titanium Gr 5. The equipment used by Astrolite can identify the alloy and distinguish between the alloys. 2 levels of test procedures are utilized.

• AQL of rods in a production batch tested

• *100% of the rods in a production batch tested

Astrolite implemented the TEAS process in the late 1980’s and the Handheld XRF process in 2019. With years of experience in both methods of PMI and strict control of our manufacturing processes Astrolite is confident in our ability to verifiably prevent FOD and escapes of mixed alloys.

Astrolite alloys is the world’s leading supplier of High performance welding wire for aerospace, power, commercial and challenging applications. With Locations in Oxnard California and our Sister facility Tricor Alloys located in Wooster Ohio we are best positioned with locations and inventory to meet the growing demands of the complex markets we serve.

*Very time consuming with added cost incurred