Explosion Clad Pressure Vessels / Columns / Heat Exchanger and Piping

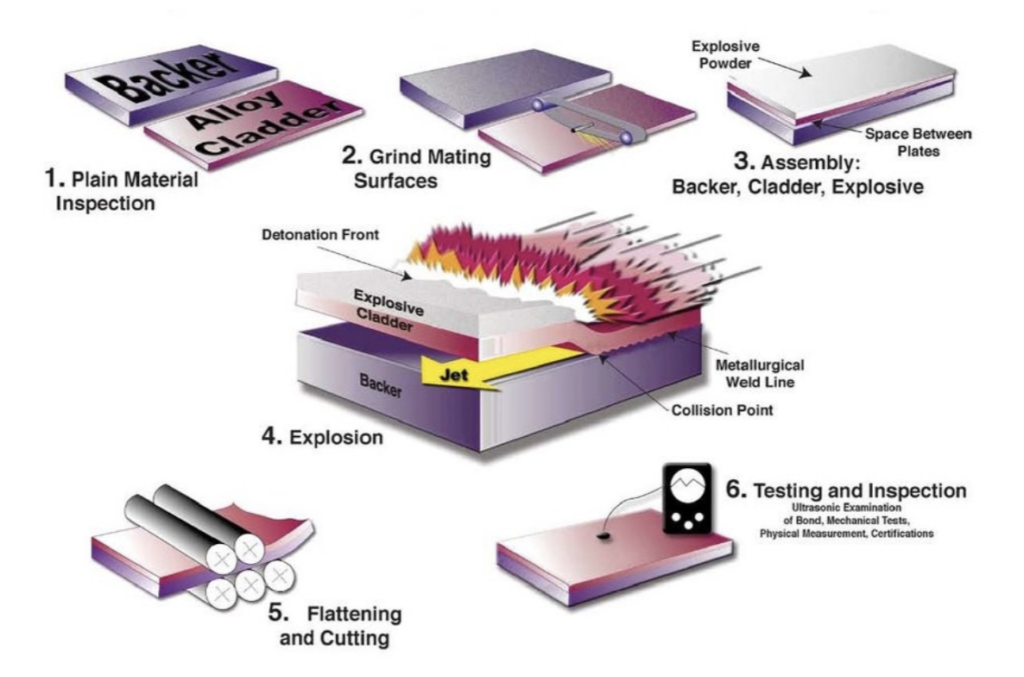

Explosion clad technology is a process of joining two dissimilar metals or alloys by using explosives to create a metallurgical bond. This technology involves placing two metal plates together with a layer of explosive material on top of them. When the explosive charge is detonated, explosion generates a high-speed collision between the two plates, causing them to bond together.

The explosive charge used in this process is carefully calibrated to ensure that the force generated is sufficient to bond the metals together without damaging them. The choice of explosive material and the amount used depends on the thickness, size, and type of metals being bonded.

The explosion causes a wave of energy to propagate through the two plates, resulting in a plastic deformation of the metal surfaces in contact. The high pressure and temperature generated by the explosion cause the atoms at the interface of the two metals to diffuse, creating a metallurgical bond between the two plates.

The explosion clad technology is used to create clad plates for a variety of industrial

applications, including oil and gas, chemical processing, and shipbuilding. Clad plates are used in these industries because they offer superior corrosion resistance, higher mechanical strength, and better durability compared to monolithic metals. They are also used to reduce costs, improve performance, and increase the lifespan of equipment.

Overall, explosion clad technology is an efficient and cost-effective method of joining two dissimilar metals or alloys and creating high-quality clad plates for industrial applications.

Figure 1- Diagram courtesy of Nobel Clad, Broomfield, CO

Explosion clad design technology can be utilized to reduce equipment costs in higher alloy pressure vessels, columns, heat exchangers and piping by reducing the amount of premium alloy used in the equipment being fabricated. Usually in order to for explosion clad to be a cost competitive option for consideration the design thickness of the cladder (Premium Alloy) material thickness in a solid design need to be greater than .625” for reactive metals and high nickel alloys and approximately 1” thick for austenitic and duplex stainless steels.

Materials commonly used in explosion clad designs are as follows:

• Austenitic Stainless Steel

• Duplex Stainless Steel

• Monel

• Inconel

• Hastelloy

• Titanium

• Zirconium

• Niobium

• Tantalum